Bush

What Are Bushes?

What are Bushes Used For?

Materials for Bushes

Common Types Of Bushes include

Rubber Bushings

Polyurethane Bushings

Babbit Bushings

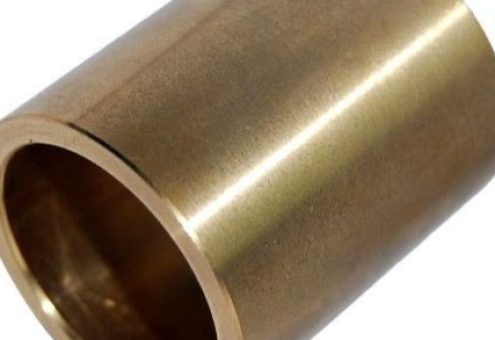

Bronze Bushings

Cast-Iron Bushings

Neoprene Bushings

Nylon

Delrin or Acetal

Ultrahigh-Molecular-Weight Polyethylene (UHMWPE)

Carbon-Graphite

Polyimide, Polysulfone, Polyphenylene Sulfidec

Common features of bushings include

Coatings

Grooves

Indents

Related Questions

While its primary function is to reduce friction and noise between two surfaces that rotate or slide against each other, a bushing also serves several additional purposes.

It serves as a guide for installing other elements in a system.

It may be inserted into a housing to limit the size of an opening or resist abrasion.

It functions as a lining through which a conductor passes, providing insulation and protection for the conductor.

It is an adapter for joining pipes of different sizes.

Most bushings are manufactured in a cylindrical or conical shape, using wear-resistant and shock-absorbent materials. They are made to slide over rods or shafts, providing extremely low-friction motion and protecting more critical parts.

Where mechanical components inevitably deteriorate over time, it’s cheaper and easier to replace a bushing than a complex piston suspension component. Bushings also work to minimise energy usage, reduce noise, absorb vibration, and protect the equipment from overall wear and tear.

A bushing’s location depends on the application. Most of the time, bushes are mounted on parts where vibration and friction are common.

In cars, bushings are found on automotive suspension systems, sway bars, transmission gear sticks, doors and windshields. In steam turbines, bushings are installed in the valve components, such as the main stop valve, control valve, extraction valve and reheat stop valve. In air compressors, bushings connect the air compressor piping to threads.

Bushes may be small, but they play a vital role in a machine’s efficiency and longevity. They isolate noise, vibration and shock, allowing the moving components to operate smoothly while providing added resistance to abrasion and damage.

Bearings

‘Bearings’ is a general term that refers to any mechanical component designed to support a rotating body and reduce friction between moving parts. It facilitates high-speed movement while handling stress and ensuring rotation is accurate.

Technically, bushings or bushes can be considered a straightforward kind of bearing – also referred to as a ‘plain bearing’.

Bearings are typically more complex in construction than bushings, typically consisting of several rollers or balls. Unlike bushings that need only a small amount of lubrication, bearings require constant lubricant supply to prevent damage and wear.

Bearings are divided into two main classes: journal bearings, where the load acts at right angles to the axis, and thrust bearings, where loads are parallel to the axis. In addition to plain bearings or bushings, common types of bearings include roller bearings, fluid bearings, magnetic bearings, flexure bearings and moulded plastic bearings.

Bushings

As mentioned, bushings are a specific subtype of bearing. They support a component in an assembly, ensuring smooth operation and reducing machine wear-and-tear. Unlike bearings composed of multiple parts, a bushing often comes as a single component. However, it can be equipped with rolling elements for sliding or support. Compared to bearings, bushings are more durable and require less maintenance because they have no moving parts.

Similarities between bushings and bearings

Both bearings and bushings reduce rolling friction between a shaft and an attached part. Hence, they both reduce friction energy losses, risk of wear-and-tear damage and repair and maintenance expenses.